Cupola M2

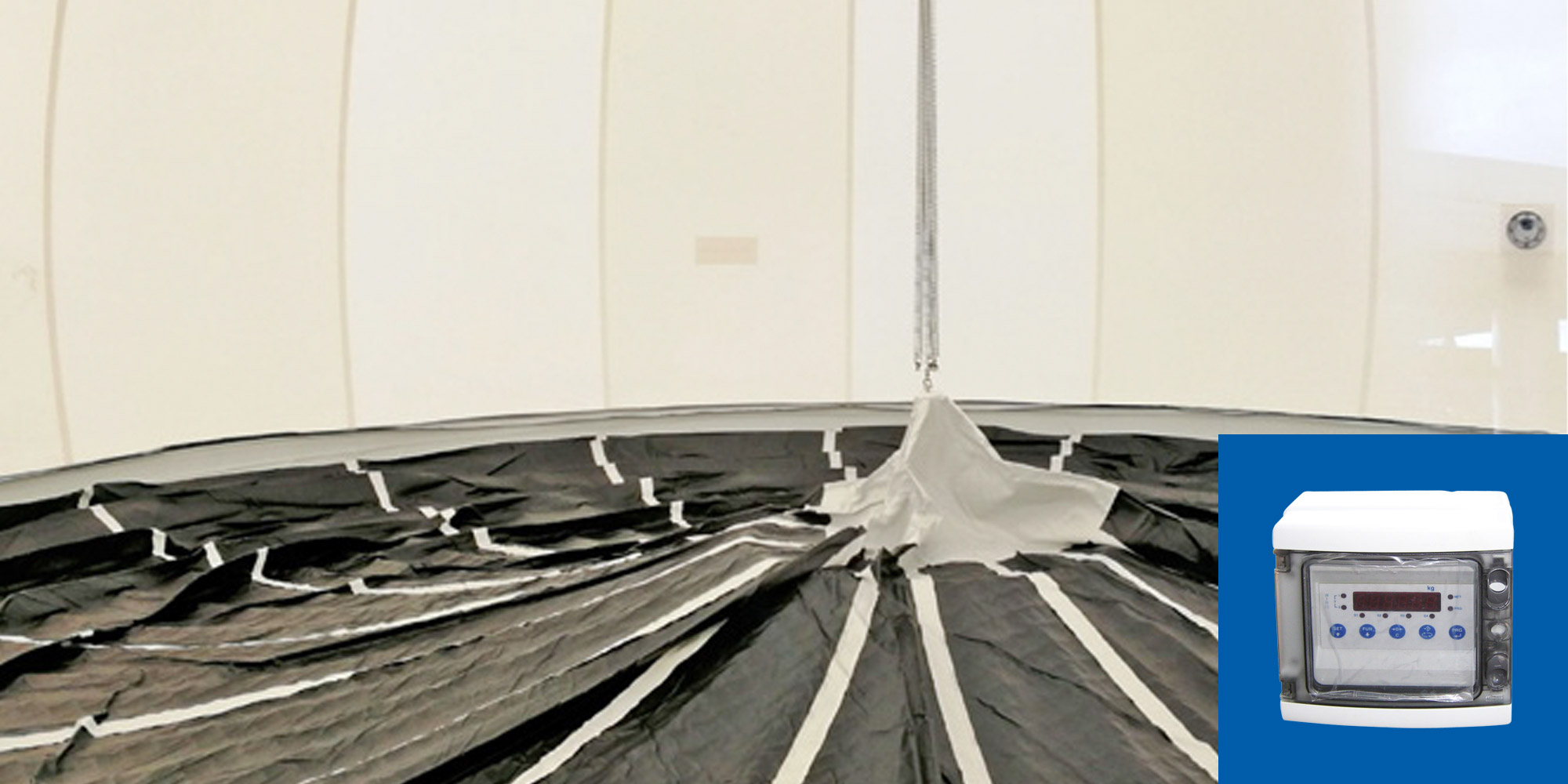

Heat Shield

option

The main objective of the CUPOLA M2 HEAT SHIELD option is maximum reduction of heat dispersion from the digester.

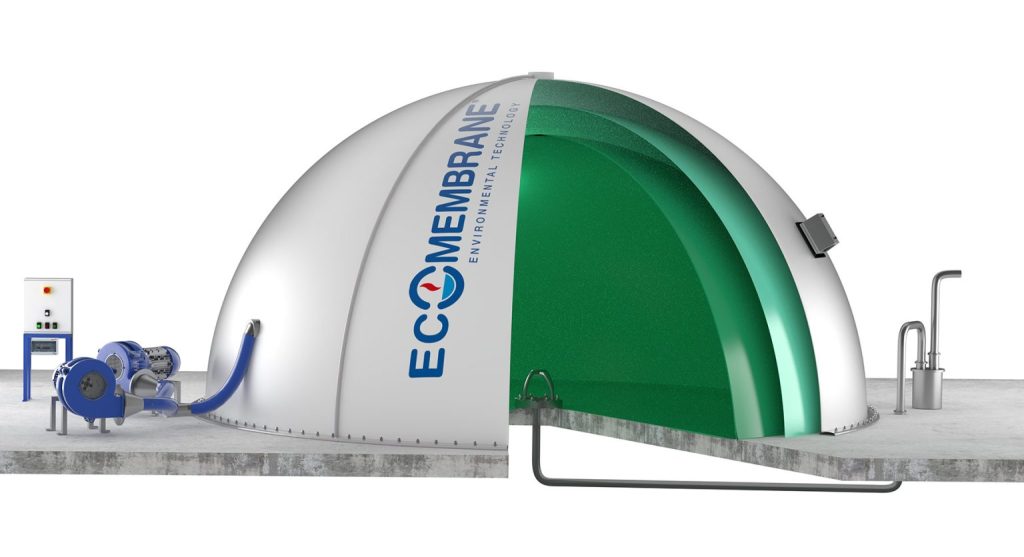

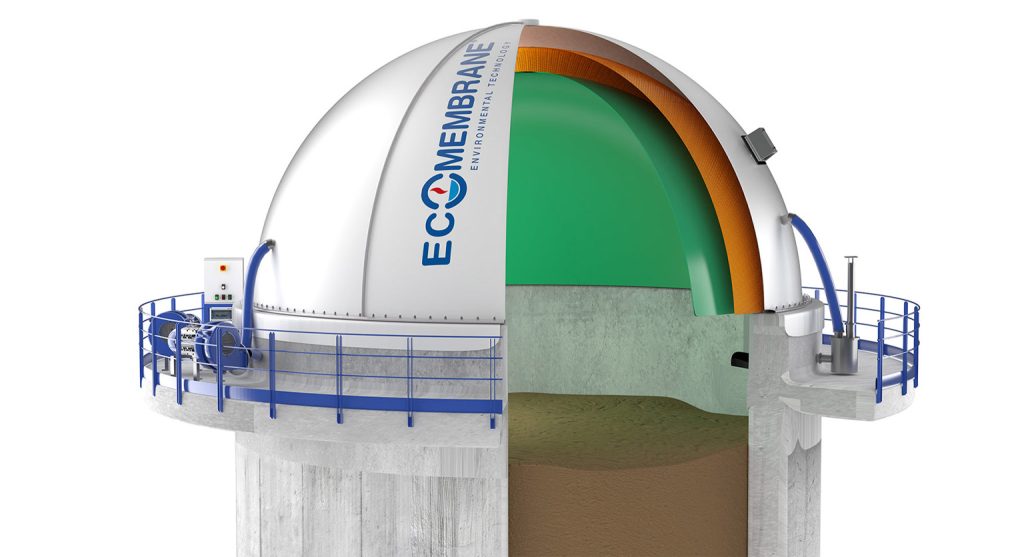

CUPOLA M2 HEAT SHIELD option consists of 3 different membrane layers which work to form a cover over the digester:

The outer fabric is in polyester PVC-coated fabric and is pressurised with air.

The special insulated Heat Shield intermediate membrane, made from a triple layered ultra-shielded material to separate the lower gas chamber from the upper air chamber. The special layers of this membrane provide protection against heat dissipation as follows:

1) A layer of aluminium reflects 96% of the radiating infrared heat.

2) A layer of bubble polyethylene sheet reduces heat loss trough convection.

3) A layer of pure polyethylene sheet provides the air chamber with a high gas tightness thus protecting the gas chamber against oxidation.

The internal gas membrane in PVC-coated polyester fibre is equipped with a special Eco-Safe layer to protect the welds.

The CUPOLA M2 HEAT SHIELD option is pressurised by a reduced power air fan operating 24/7 and is regulated by a special valve which forces the air to enter the air chamber only in the event that the pressure in the gasholder dome drops.

Thanks to this combined system, there is a limited air exchange in the chamber itself with a reduction in the heat loss due to the reduced influx of cold air. This effect can only be achieved in a 3-membrane gasholder dome, because there is no need for the constant replacement of safety air. This is due to the physical barrier created by the intermediate membrane between the two independent chambers (air and gas).

ADVANTAGES

50% reduction in heat loss

Reduction in heat dissipation: consequently the energy costs to heat the digester are drastically reduced. The economic return times are quickly reduced thanks to the massive energy savings.

Reduced electricity consumption

The 3-membrane system benefits from its intrinsic safety and requires a low electricity consumption fan.

Passive safety against the danger of explosion

The insulating layer of the intermediate membrane creates the complete separation between the air chamber and the gas chamber. No possible gas leak can enter the air chamber, which means no explosive mixture can form

Greater durability of the internal gas membrane

Since the gas membrane is covered entirely by the intermediate (matt) membrane, protection against ultraviolet light and exposure to direct oxidation caused by the air pumped by the fan is obtained.