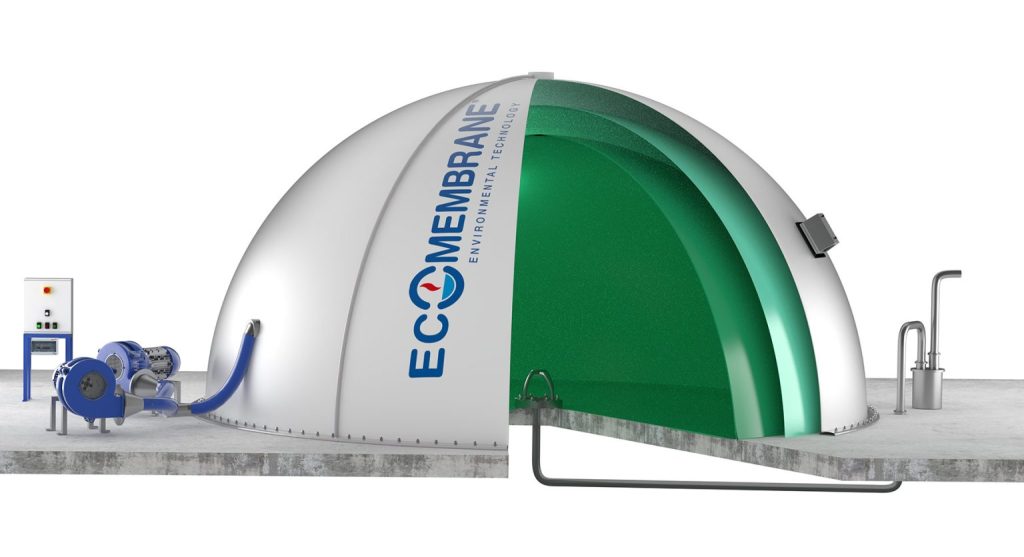

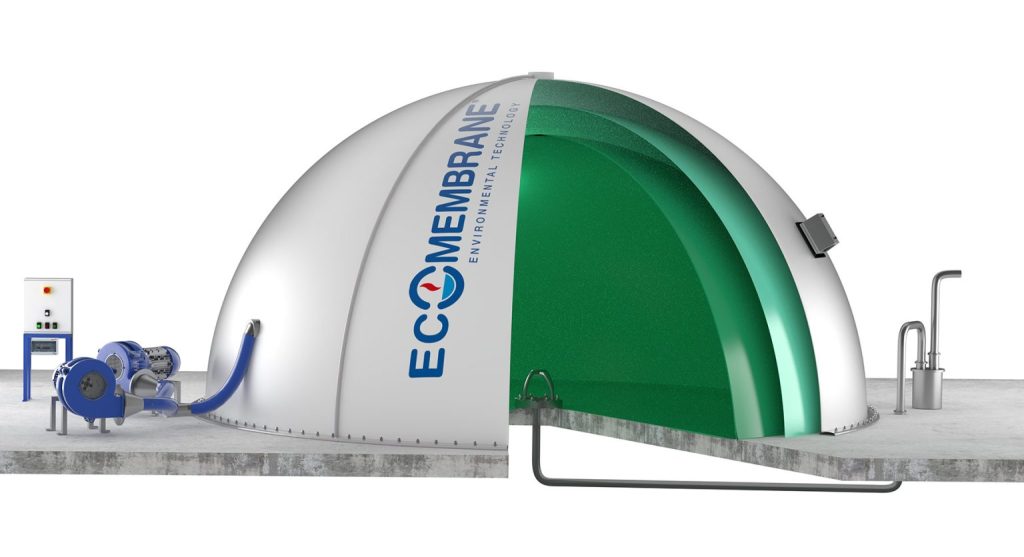

The third membrane is completely separate from the air membrane to avoid explosive mixtures.

They are made with biogas resistant PVC-coated polyester fibre fabric membranes seam welded by high frequency electronic machines.

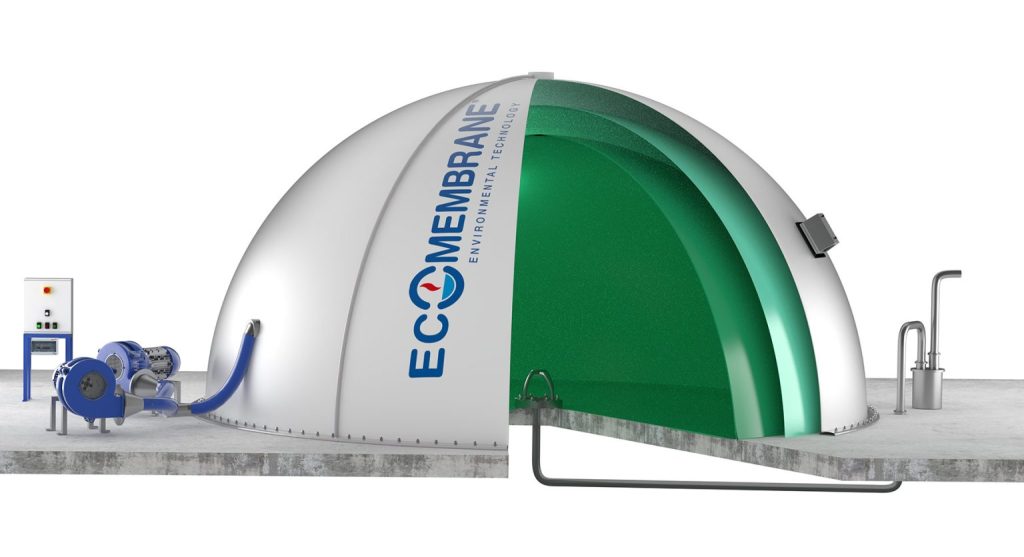

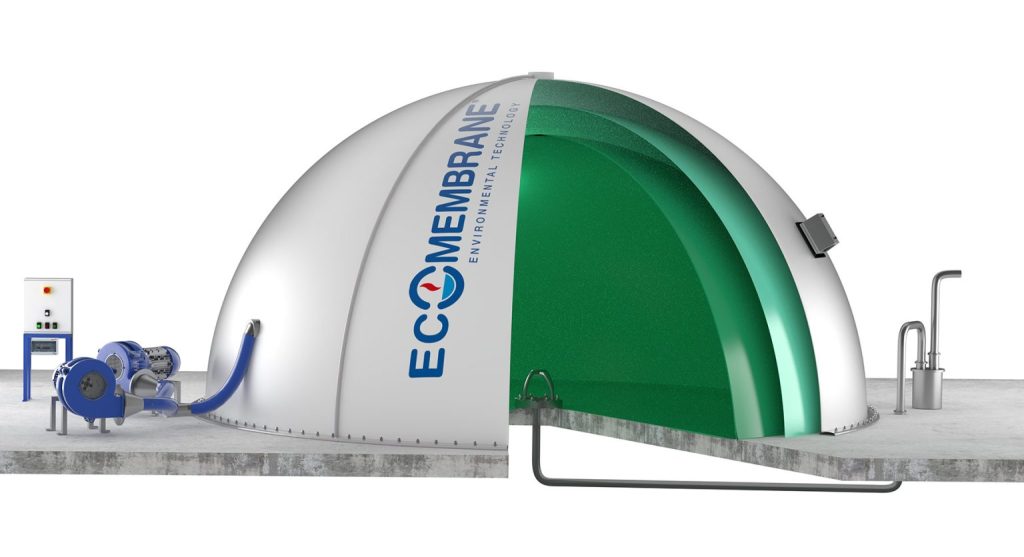

The 2MASTER system is made with a single outer membrane which is pressurised by an air fan 24 hours a day to give a pneumatic push on the biogas chamber underneath. The one-piece gas chamber can be made in the factory, or on site. Closed piece construction prevents gas losses through the anchor bolts that fix the cover to the ground.

ECOMEMBRANE’S patented 3 membrane system negates any possibility of a gas and air explosive mix because the biogas chamber is completely divided from the air compensation chamber.

The compensation air blower only operates when the biogas is being used from the gasholder and switches off when the gasholder is filling. The air blower is controlled by a pressure sensor and an air valve is fitted to the air chamber and set to limit the maximum operating pressure ensuring constant pressure of the biogas throughout the filling and emptying cycle.

2 MASTER and 3 MASTER gasholders are UV resistant and designed to withstand substantial wind and snow loadings. The internal membrane is biogas tight